Share this

Swagelok's Fast Loop Modules Give Analyzers a Big Boost

by Katie Dennis on Tue, Aug 13, 2013 @ 11:08 AM

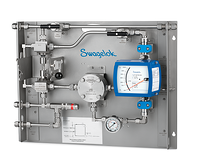

PrESS FLM could be the solution to your analyzer problems

|

A typcial FLM system |

A long distance between a sample tap and an analyzer shelter can make it difficult to obtain a useful analytical measurement. Ideally, the flow from the tap to the shelter should take a minute or less. But transport lines often are more than 30 metres and require high purge volumes to ensure that a fresh sample reaches the analyzer.

That's where a fast loop module, also called a bypass loop, can be a great addition to a system. Fast loop modules are designed to handle high flows in sample transport lines to reduce time delays for online analyzer systems. Located at the analyzer shelter and offering a bypass, the Swagelok fast loop module can isolate the sample system and introduce a purge gas for system cleaning.

Edmonton Valve & Fitting offers these modules as pre-engineered subsystems. Because Swagelok has worked out the design already, the fast loop module can be available with a single ordering number in weeks, not months. It offers a lot of advantages over trying to put something together on your own from available parts.

"You'll find the functionality is improved from what people have done in the past," says Jim Smart, one of our account managers. "Then there are some safety features. With the interlocking handle design, users can be confident about opening them in the right sequence."

The Swagelok design includes two ball valves that switch flow to a bypass to isolate the sample system and analyzer during maintenance. These bypass valves maintain flow through the fast loop to keep the sample fresh at the bypass point. The interlocking handles allow for simultaneous actuation of the valves, while allowing for packing adjustments within an individual valve body. In some configurations, the drain and purge valves are locked into the bypass valves to eliminate the possibility of opening the drain or purge lines while the system is in sample mode. All handles can be locked into position to eliminate the possibility of accidental actuation.

Multiple configurations

The base model, described in Swagelok's application guide, download here, allows the fast loop to be bypassed when the analyzer is not in use. From there, Swagelok can create several configurations: with a return from the analyzer to the process line, with a return from the analyzer to a drain, or with a gas or liquid purge and manual drain.

An optional grab sample outlet and a relief outlet are available with all FLM configurations. All configurations also are designed to enable easy access to any component without disturbing other components in the system. Swagelok uses welded assemblies to reduce potential leak points and zero clearance fittings in straight run tubing sections.

No water hammer

Closing a valve in a high-flow liquid line causes extreme pressure spikes, referred to as water hammer, which can damage system components. Our fast loop module eliminates the possibility of water hammer by making full shutoff impossible. The bypass valves actuate simultaneously to eliminate the possibility of actuating only one of the valves. The three-way valve design allows flow to switch gradually from sample mode to bypass mode, instead of temporarily shutting off during actuation.

You can get fast loop modules in the 1/4 in. size, used mainly for gas samples, or the 1/2 in. size, which is usually best for liquid samples.

There's no need to re-invent the wheel, or the fast loop module. Swagelok has done the work. Let Edmonton Valve & Fitting show you how to reap the benefits, contact us today!

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)