Share this

Webinar Gives Detailed Look at Swagelok Pre-Engineered SubSystems

by Katie Dennis on Wed, Oct 03, 2012 @ 09:10 AM

Since you couldn’t travel hundreds of miles to see them in person, we have put our demo online

Have you ever wished that you could grab an off-the-shelf solution instead of having to design your own subsystems? A lot of customers have felt that way. We know because Swagelok has listened to its customer advisory board. They wanted an array of subsystems designed to their specs, ready to plug and play.

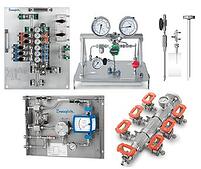

The result is what we call Pre-Engineered Subsystems, or PrESS for short. It’s a series of Swagelok components predesigned and pre-assembled for use anywhere that fluids are processed. They range from simple weldments to complex manifolds. The list includes fluid distribution headers, sample probe modules, calibration and switching modules, and others. We’re continuing to add to the list.

Earlier this summer some Swagelok customers in California got a chance to see five versions of the new PrESS assemblies in person. Thanks to the cooperation of offices across Swagelok’s global distribution network, you can see that same presentation without leaving Alberta.

The webinar was led by two experts: Doug Nordstrom, analytical instrumentation market manager, Swagelok; and Tony Waters, an industry expert and consultant to the field. Nordstrom focuses his efforts on advancing Swagelok’s involvement in sample handling systems. Waters has 30-plus years of experience with sampling systems and is an expert in the application of process analyzers in refineries and chemical plants.

Together they demonstrated how PrESS can save a company time and money.

Waters discussed the use of standardized subsystems for capturing, conditioning, and transporting process samples to analyzer systems, and how this approach can mean quicker installations, easier maintenance, better system performance, and lower cost of ownership. The idea is to replace time consuming, from-scratch sub system design, which are engineered to order, with discrete components that are predesigned and easily available. It’s ideal for repeat applications in typical analyzer systems. It means you get standard configurations and layout consistency at the lowest possible installed cost. They even come with user manuals and a warranty.

Nordstrom and Waters illustrated the savings by showing how one sample system would take 135 total part numbers and 54 hours of assembly to create from scratch. Creating the same system from PrESS assemblies cuts the order down to 17 part numbers and only 6 hours of assembly.

The webinar then went through five specific examples to show how PrESS works in real life.

* Calibration and Switching Modules -- These highly configurable units are built with Swagelok modular platform component (MPC) products, that perform final conditioning of sample before analysis. Select from up to 10 sample and 2 calibration streams using the Swagelok stream selector system (SSV series).

* Fast Loop Modules -- Designed for handling long transport lines from tap to analyze, these modules are built for minimum pressure drop for the fastest response time. Interlocking handles help prevent incorrect sequence of operation.

* Field Station Modules -- These assemblies are used to precondition a gas sample at the extraction point. It is highly configurable to match process conditions and can mount directly to process nozzles.

* Fluid Distribution Headers – The headers have versatile manifolds for gas and liquid applications and Swagelok components for reliability. Fluid distribution headers can be connected inline to create longer lengths.

* Sample Probe Modules -- These modules include a wide range of probes for various applications. Probe interlocks protect equipment and valve interlocks improve safety of operation.

PrESS assemblies arrive at your door ready to go. You don’t have to build an inventory of components, or figure out what to do with the ones that don’t conform to specs. By working directly with Edmonton Valve & Fitting, you avoid mark-ups and administrative costs of middleman suppliers. And the assemblies come with Swagelok’s expertise behind them.

In the meantime, you can see the 30-minute briefing yourself right here. Afterwards, give us a call and let us know how we can put PrESS to work for you.

Share this

- Local Services (103)

- Field Advisors (101)

- Training & Events (86)

- Fittings (81)

- Valves (66)

- Resources (62)

- Tubing (62)

- Sampling Systems (60)

- Design & Assembly (57)

- Resources - Downloads (40)

- Hose & Flexible Tubing (39)

- Frequently Asked Questions (37)

- Regulators (34)

- Cost Savings (33)

- Oil & Gas (33)

- Videos (33)

- Steam Systems (29)

- Mechanical Seal Support (17)

- Measurement Devices (15)

- Gas Distribution Systems (9)

- Rentals (6)

- winterization (6)

- Safety (5)

- Covid (3)

- Hydrogen & Clean Energy (2)

- About Us (1)

- April 2024 (2)

- March 2024 (2)

- January 2024 (3)

- December 2023 (2)

- November 2023 (3)

- October 2023 (2)

- September 2023 (3)

- August 2023 (3)

- July 2023 (3)

- June 2023 (2)

- May 2023 (4)

- April 2023 (2)

- March 2023 (2)

- February 2023 (3)

- January 2023 (2)

- December 2022 (1)

- November 2022 (1)

- October 2022 (2)

- September 2022 (5)

- August 2022 (3)

- July 2022 (6)

- June 2022 (4)

- May 2022 (3)

- April 2022 (1)

- March 2022 (2)

- February 2022 (3)

- January 2022 (4)

- December 2021 (4)

- November 2021 (6)

- October 2021 (3)

- September 2021 (5)

- August 2021 (9)

- July 2021 (5)

- June 2021 (7)

- May 2021 (7)

- April 2021 (4)

- March 2021 (3)

- February 2021 (3)

- January 2021 (2)

- December 2020 (3)

- November 2020 (3)

- October 2020 (2)

- September 2020 (3)

- August 2020 (3)

- July 2020 (3)

- June 2020 (3)

- May 2020 (3)

- April 2020 (2)

- March 2020 (3)

- February 2020 (3)

- January 2020 (3)

- December 2019 (2)

- November 2019 (3)

- October 2019 (3)

- September 2019 (2)

- August 2019 (3)

- July 2019 (2)

- June 2019 (2)

- May 2019 (3)

- April 2019 (3)

- March 2019 (3)

- February 2019 (2)

- January 2019 (3)

- December 2018 (2)

- November 2018 (2)

- October 2018 (4)

- September 2018 (2)

- August 2018 (3)

- July 2018 (3)

- June 2018 (2)

- May 2018 (4)

- April 2018 (3)

- March 2018 (3)

- February 2018 (3)

- January 2018 (4)

- December 2017 (1)

- November 2017 (4)

- October 2017 (4)

- September 2017 (4)

- August 2017 (5)

- July 2017 (3)

- June 2017 (4)

- May 2017 (4)

- April 2017 (3)

- March 2017 (5)

- February 2017 (4)

- January 2017 (4)

- December 2016 (3)

- November 2016 (3)

- October 2016 (4)

- September 2016 (3)

- August 2016 (4)

- July 2016 (2)

- June 2016 (2)

- May 2016 (2)

- April 2016 (4)

- March 2016 (2)

- February 2016 (3)

- January 2016 (4)

- December 2015 (4)

- November 2015 (4)

- October 2015 (5)

- September 2015 (2)

- August 2015 (4)

- July 2015 (5)

- June 2015 (2)

- May 2015 (3)

- April 2015 (5)

- March 2015 (3)

- February 2015 (4)

- January 2015 (3)

- December 2014 (5)

- November 2014 (4)

- October 2014 (4)

- September 2014 (4)

- August 2014 (4)

- July 2014 (5)

- June 2014 (4)

- May 2014 (4)

- April 2014 (5)

- March 2014 (4)

- February 2014 (4)

- January 2014 (4)

- December 2013 (3)

- November 2013 (4)

- October 2013 (5)

- September 2013 (4)

- August 2013 (5)

- July 2013 (4)

- June 2013 (3)

- May 2013 (4)

- April 2013 (5)

- March 2013 (2)

- February 2013 (3)

- January 2013 (5)

- December 2012 (3)

- November 2012 (3)

- October 2012 (5)

- September 2012 (3)

- August 2012 (4)

- July 2012 (4)

- June 2012 (1)